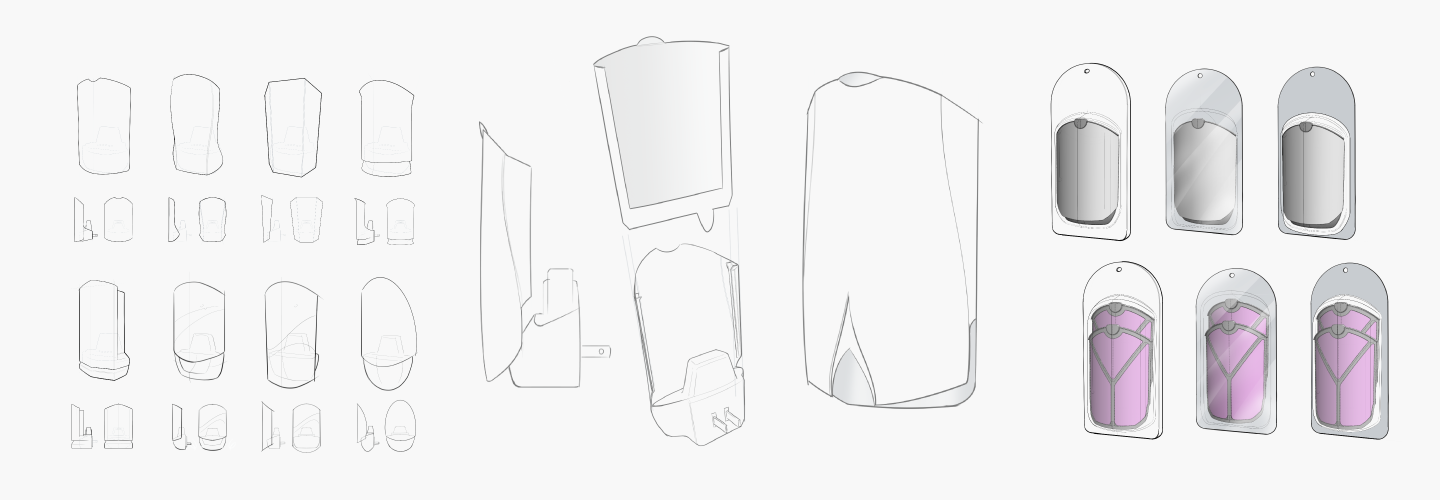

Starting with existing light activation technology, we began the project in a traditional industrial design mindset, sketching quickly with iterative form studies. Once we were able to narrow down on the curved shape of the device, we began to troubleshoot the interaction between the consumer and the product, moving into 3D modeling and then 3D printing multiple versions of the refill cartridges.

This allowed us the opportunity to test designs in real-time, solving for a variety of problems at once. By adding sliding rails with tapered openings, consumers could quickly and easily slide the refills in place without frustration. We added the "keystone" at the top of cartridge, making it intuitive for consumers to grab the refill while keeping their hands away from any potential bugs. We also added the Zevo logo to the keystone, leveraging it as an additional branding opportunity. We were even able to overcome the injection molding restrictions, solving through several iterations how to use the least amount of plastic while still maintaining the structural shape.

The ZEVO plugin was such an overwhelming success for P&G that we were also contacted to develop the Zevo Max, using the same refill geometry but creating a 360° experience while preserving the brand form language.